7 Considerations When Moving Complex Pharma Equipment into Your Lab

Moving complex pharma equipment and systems into your lab is not your everyday project.

We're actively recruiting for a range of roles across sales, engineering, IT and warehouse. Check our careers page to see open positions including apprenticeships.

At IES, we love a challenge. In fact, the more complex the project is, the better.

Few complex engineering projects compare to the challenge of relocating sensitive, high-technology equipment across borders.

At IES, we partner with leading global manufacturers to provide an extensive portfolio of advanced technologies supporting research, development, and production across the semiconductor and compound materials industries.

Whether you’re moving a single piece of equipment or an entire production line, our trusted team of engineers can support every step of your move, from rigging to end-to-end relocation support across the globe.

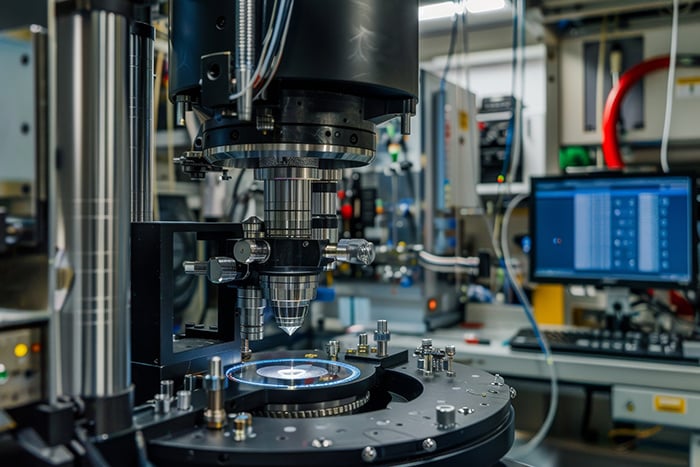

The pharmaceutical sector is continuously evolving. And as facilities scale up production, reconfigure cleanrooms, or introduce new technologies, the need to move critical equipment safely and efficiently becomes a high priority.

But relocating pharmaceutical machinery isn’t simply a logistical challenge. It requires careful coordination, technical precision, and a firm understanding of the regulatory landscape.

With highly sensitive systems, strict contamination controls, and complex utilities involved, there’s simply no room for error.

In this article, we explore the 4Ps of moving pharmaceutical equipment. Whether you’re preparing for a small lab reorganisation or a full-scale site transition, these principles will help ensure a compliant and controlled move.

See our article: 7 Considerations When Moving Complex Pharma Equipment into Your Lab

Without the right people, can you expect the right result?

A successful pharmaceutical relocation starts with selecting the right service provider. Get it wrong, and you risk damage, project delays, unexpected costs and more.

To reduce the chances of that happening, we recommend partnering with an expert, end-to-end relocation specialist who can manage every aspect of the project, from decommissioning and rigging, to transportation, reinstallation, and compliance testing.

With an end-to-end provider, you can expect:

See our article: What To Ask Your Capital Equipment Relocation Partner Before Starting a Project.

Planning is the backbone of any successful move. And that starts with creating detailed relocation plans tailored to each project. This should outline:

Our complex laboratory move for Pirbright Institute is an example of how important planning is to the pharmaceutical relocation process. See the case study here.

Another key area is insurance.

Your relocation provider should clearly explain your coverage options. But we recommend always reviewing your current policy to ensure there are no gaps, exclusions, or hidden clauses that could leave you exposed to dispute or liability. Read our guide to getting the right cover here.

Finally, your planning process should include schedule optimisation. You’ll need to work closely with your team to minimise downtime, whether that means coordinating moves around production shifts, conducting out-of-hours work, or phasing the relocation.

Read more: 6 Things to Consider When Planning an Equipment Relocation Project.

A well-prepared move prevents costly mistakes.

To make that happen, you’ll need to conduct detailed risk assessments at every stage (from decommissioning, packing and rigging, to transport, and reinstallation) to ensure equipment remains protected and regulatory requirements are met. See our blog, Why Are RAMS So Essential for Lab Equipment Movers?, for more.

Protective packaging is also especially critical when moving sensitive instruments, high-value lab equipment, or cleanroom systems. So, be sure to plan your packaging in advance.

We recommend selecting materials tested for moisture resistance, vibration absorption, and structural integrity. Custom crating or shock-absorbing pallets may be required depending on equipment type.

See our article: Packing High-Technology Equipment: An Expert’s Guide.

Finally, being well-prepared involves coordinating utilities at the receiving site. Ensure infrastructure for power, compressed air, gas, drainage, or data connectivity is ready before installation. Otherwise, you could run into issues and delays at the other side.

Relocation doesn’t end with delivery.

There’s still much to do after the move is complete. This includes:

For equipment used in regulated environments, compliance testing is non-negotiable. This may include:

Post-move documentation should be clear and audit-ready, covering calibration, IQ/OQ protocols (Installation and Operational Qualification), and any modifications made during the move.

For more than 30 years, we’ve been working with complex biotechnology, life sciences, medical and pharmaceutical equipment in laboratories and cleanrooms worldwide.

Our all-in-one, start-to-finish service covers every step of your equipment relocation, from single production lines to full-site relocations.

See our pharmaceutical equipment moves service page here for more information.

Stay up to date with the latest news and resources from our experts.

Moving complex pharma equipment and systems into your lab is not your everyday project.

Planning a complex capital equipment relocation and looking for the right partner to support the project?

Whether you’re moving sensitive instruments like electron microscopes and spectrometers or high-powered lasers and centrifuges, relocating lab...