How To Design and Install a Structural Machine Base

Using a well-made structural machine base versus a substandard base can be a matter of life or death for precision tools like lithography, metrology...

We're actively recruiting for a range of roles across sales, engineering, IT and warehouse. Check our careers page to see open positions including apprenticeships.

At IES, we love a challenge. In fact, the more complex the project is, the better.

Few complex engineering projects compare to the challenge of relocating sensitive, high-technology equipment across borders.

At IES, we partner with leading global manufacturers to provide an extensive portfolio of advanced technologies supporting research, development, and production across the semiconductor and compound materials industries.

Whether you’re moving a single piece of equipment or an entire production line, our trusted team of engineers can support every step of your move, from rigging to end-to-end relocation support across the globe.

5 min read

Admin Updated on August 1, 2025

You’ve spent the past few weeks relocating, installing and setting up a piece of high-technology capital equipment.

Now there’s just one more vital step before you can put that equipment into operation: commissioning.

Commissioning involves running a series of tests and checks to validate that the equipment is fully operational, safe for use and able to work to the required specifications.

In this article, we’ll share the seven key stages of commissioning high-technology capital equipment—including the key considerations and best practices.

Start by obtaining a solid definition of the equipment’s performance objectives and technical specifications (including performance metrics and environmental conditions). These will serve as the criteria to test against during validation.

Next, assemble a team of mechanical engineering, electrical engineering, software development, quality assurance, and operations management professionals to carry out the project.

Lastly, work closely with your team to develop a detailed commissioning plan that outlines every step required to bring the equipment to full operational status. This should include:

Once you’ve put your plan together, you’re ready to start performing your checks and tests.

Installation checks are crucial for verifying that the equipment has been installed and set up according to the precise specifications of the original equipment manufacturer (OEM).

They involve conducting a thorough inspection of both the physical and functional set-up of the equipment, including:

Dry testing (or pre-energization testing) involves rigorously testing mechanical components to ensure they’ve been properly installed and are fully functional before you introduce power to the system.

This involves first performing the following checks:

Once those initial checks have been completed, the next step is to evaluate the equipment’s control systems in a simulated environment. The aim is to verify they’ve been set up correctly and are ready for operation.

This involves performing several very specific types of checks:

Integration testing: confirm the control system correctly interfaces and communicates with system components such as sensors, actuators and other machinery.

Wet testing (or energisation) involves powering up the equipment under controlled conditions. The aim is to safely and effectively check that the equipment operates efficiently and as required.

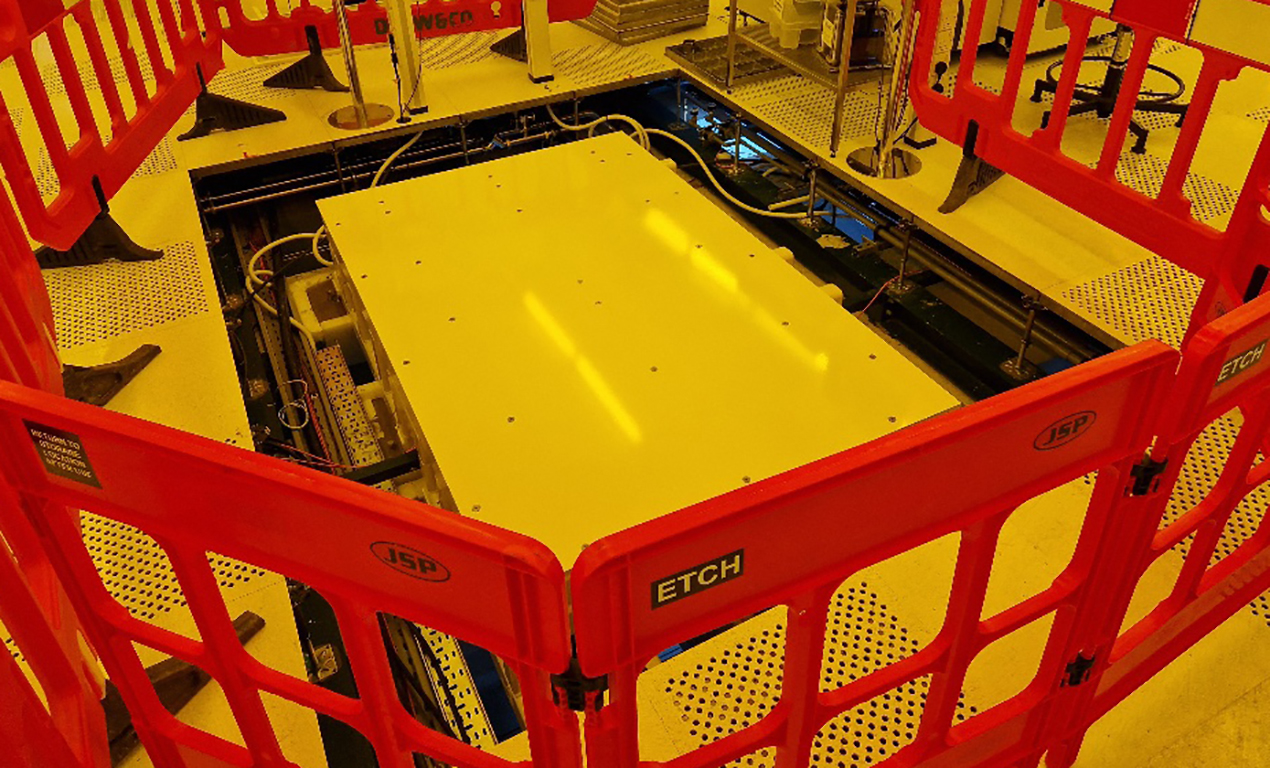

![]()

The process of wet testing involves:

Once you have completed wet testing and powered up the equipment to full operational capacity, you should then conduct functional tests to validate its operational capabilities and verify that it performs as expected under various conditions.

These include:

Validation is about ensuring the equipment meets all operational, functional and compliance requirements, as well as set quality standards.

Validation involves:

Final acceptance testing (FAT) is the final checkpoint in the commissioning process.

It involves conducting a comprehensive review to confirm that the equipment is safe, fully operational and ready to be handed over to operations.

Here are the key components of the FAT stage:

Once you’ve completed FAT and handed the equipment over to operations, we recommend monitorinh the equipment’s performance during its initial operational period to identify any emerging issues or areas for improvement.

Whether you’re installing and commissioning single machines or entire production lines, you need personnel with the right experience and knowledge to meet OEM specifications and avoid disruption or damage.

Our turnkey service covers every single part of that process, from CDM, assembly and bolt-up to start-up and commissioning.

Learn more via our Equipment Installations service page here.

Stay up to date with the latest news and resources from our experts.

Using a well-made structural machine base versus a substandard base can be a matter of life or death for precision tools like lithography, metrology...

Supporting implant equipment in fabs and cleanroom environments requires a unique combination of technical expertise, problem-solving skills and an...

Moving and installing high-technology equipment is always a challenging task, but when you add a cleanroom environment to the mix, things get even...