Machinery Safety Testing

Comply with the Supply of Machinery (Safety) Regulations/Machinery Directive with Total Confidence

If you manufacture, distribute, supply or buy certain types of high-technology machinery in the GB or EEA market, they must comply with the Supply of Machinery (Safety) Regulations/Machinery Directive, respectively.

Our start-to-finish electrical equipment evaluation service for large and medium-sized capital equipment covers every step of the process, from testing against relevant measures to compiling your technical documentation and addressing remedial actions.

- High-technology equipment specialists since 1991

- On-site assessments across the UK

- Expert consultative service

Trusted By

Further information on Machinery Safety Testing

-

What is the 2006/42/EC Machinery Directive?

2006/42/EC is the code for the Machinery Directive. This directive is a set of health and safety requirements that apply within the European Union (EU) to new and modified equipment used in the workplace.

The Machinery Directive forms part of CE marking. Demonstrating compliance with the Machinery Directive is part of the CE marking process for work equipment and machinery sold on, or supplied to, the EU and European Economic Area (EEA) markets.

-

What is the purpose of the 2006/42/EC Machinery Directive?

The purpose of the Machinery Directive is to prevent machinery and equipment from damage or harm; both to its users, and to the surrounding environment. It aims to eliminate or minimise the potential for equipment to cause hazardous circumstances, and sets out procedures for conformity assessments.

In harmonising the essential health and safety requirements for work equipment between member states of the EU and EEA, the Machinery Directive helps to remove trade restrictions and enable the free movement of equipment and machinery.

-

What does the Machinery Directive cover?

The Machinery Directive applies to new and significantly modified equipment and machinery used in the workplace.

The regulations define “Machinery” as:

“An assembly, fitted with or intended to be fitted with a drive system other than directly applied human or animal effort, consisting of linked parts or components, at least one of which moves, and which are joined together for a specific application.”

The directive also incorporates assemblies:

- Missing only the components to connect it on-site, or to sources of energy and motion.

- Ready to be installed and able to function if mounted on transport or in a building.

- Partly completed and can be arranged and controlled so that they function as a whole.

- With linked parts of components, at least one of which moves and “which are joined together, intended for lifting loads and whose only power source is directly applied human effort”.

Other items covered by the directive include:

- Interchangeable equipment

- Safety components

- Lifting accessories

- Chains, ropes and webbing

- Removable mechanical transmission devices

The types of machinery and equipment exempted from the 2006/42/EC Machinery Directive include:

- Weapons, including firearms

- Military or police equipment

- Equipment used specifically in fairgrounds or amusement parks

- Tractors and other vehicles used in agriculture and forestry

- High voltage equipment

- Research equipment intended for temporary use in laboratories

Typically, the equipment above is governed by its own EU regulations and falls outside the scope of the directive.

-

Who is responsible for compliance with the Machinery Directive?

The following parties are responsible for compliance with the Machinery Directive:

- Manufacturers, including those producing equipment for in-house use

- Parties modifying existing machinery so that it can be considered ‘new’ equipment

- Importers bringing non-CE-marked equipment into the EU or EEA for the first time

What We Do

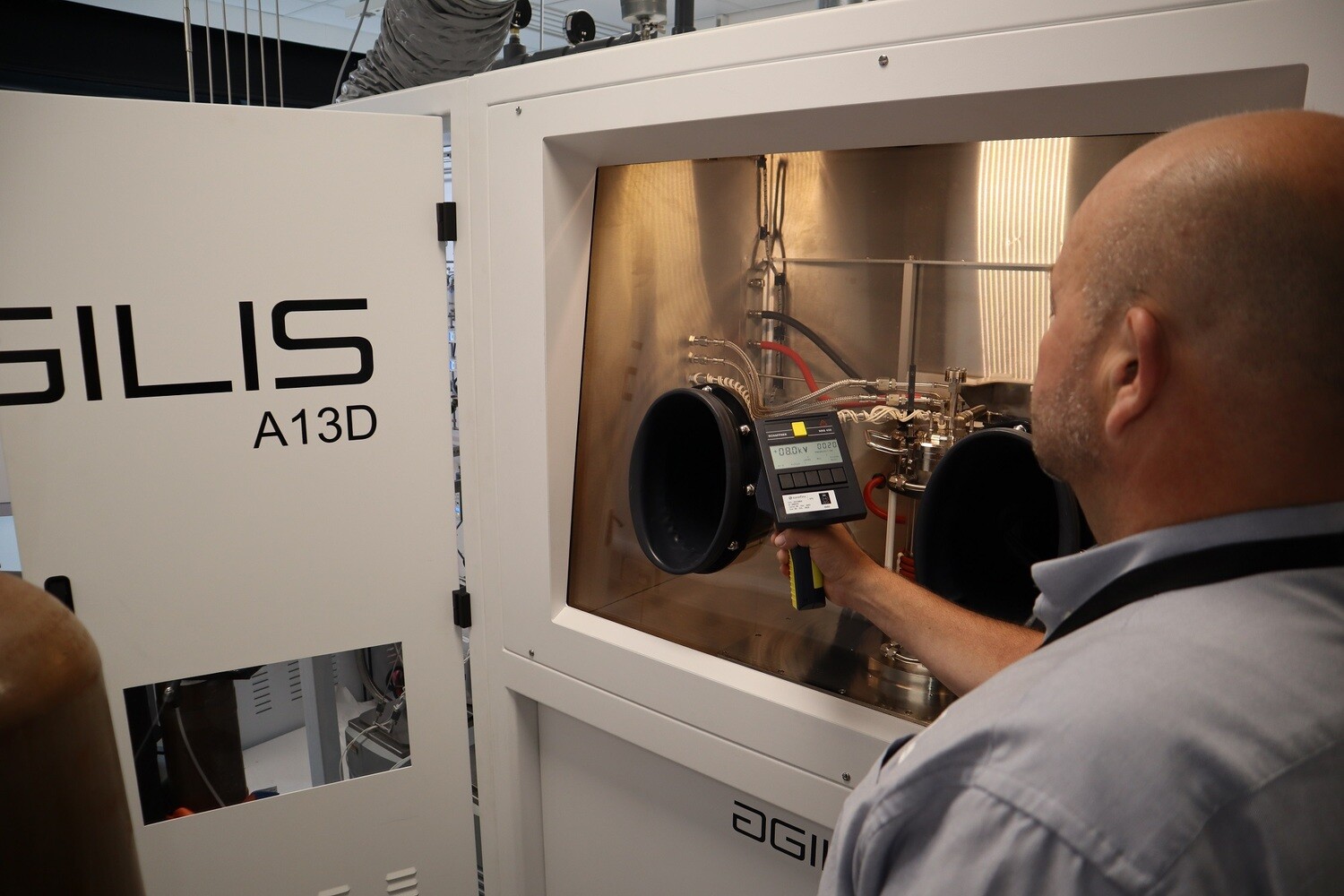

From single machines (including production tools, test rigs, automation systems and lighting controls) to assemblies and production lines, we help high-technology manufacturers and importers evaluate machinery and equipment against the Supply of Machinery (Safety) Regulations/Machinery Directive and ensure compliance. Our start-to-finish service includes:

|

|

Selection of harmonised standards for the machine functions |

|

|

Equipment inspection in accordance with BS EN ISO 12100 (either on-site or at our Bristol facility) |

|

|

Evaluation of equipment against relevant Machinery (Safety) Regulations/Machinery Directive standards |

|

|

Comprehensive risk analysis and assessment |

|

|

Full written report of test data and any non-compliance issues |

|

|

Compilation of all technical documentation |

|

|

Consultancy and support throughout, including guidance on the most appropriate remedial actions, if required |

|

|

Additional services, if required:

|

Supply of Machinery (Safety) Regulations

Learn more about the Supply of Machinery (Safety) Regulations and what they cover.

Why Work With Us?

-

35+ Years of machinery expertise

Work with a partner that has more than three decades of experience working with high-technology capital machinery and equipment

-

Thorough checks for your peace of mind

Have total confidence that your machinery and equipment has been rigorously evaluated by a specialist team and ticks every box

-

Ongoing expert help & advice

Get an ongoing expert consultancy service, including personalised guidance on the most appropriate remedial actions in the event of non-compliance

-

Specialist support

Work with a team that’s always on hand to answer any questions you might have about your equipment or the project

Our Unique Capabilities

Equipment Expertise

We’ve been working with high-technology capital machinery and equipment since 1991.

On-site Testing

We travel to your UK site to perform your equipment evaluation, or you can come to our Bristol site if preferred.

End-to-end Support

Alongside testing, we can also support UKCA/CE marking, equipment relocations, export packing and more.

Trusted by Rolls-Royce, Analog Devices, University of Bristol and more

Since 1991, we’ve been helping manufacturers and importers in the semiconductor, pharma and other high-technology industries to evaluate high-technology machinery in cleanrooms, labs and production facilities across the UK.

How we helped the University of Bristol carry out Supply of Machinery (Safety) Regulations/Machinery Directive 2006/42/EC tests on their new metal organic chemical vapour deposition (MOCVD) machine, helping them achieve UKCA and CE compliance.

Speak with one of our experts

Request a callback from one of our team or book a site survey for your project.