Electrical Equipment Safety Testing

Comply with the Electrical Equipment (Safety) Regulations/Low Voltage Directive (LVD) with total confidence

As a high-technology manufacturer, certain types of electrical equipment that you sell or supply to the GB or EEA market must comply with the Electrical Equipment (Safety) Regulations/Low Voltage Directive (LVD), respectively.

Our start-to-finish electrical equipment evaluation service for large and medium-sized capital equipment covers every step of the process, from testing against relevant measures to compiling your technical documentation and addressing any remedial actions.

- Electrical equipment specialists with 35 years of experience

- On-site assessments across the UK

- Expert consultative service

Trusted By

Further information on Electrical Equipment Safety Testing

-

What is the Low Voltage Directive?

The Low Voltage Directive (LVD) specifies health and safety obligations for electrical equipment. It applies to equipment intended for use within certain voltage limits. The LVD is relevant to manufacturers and distributors supplying or selling electrical equipment in the European Union (EU) and European Economic Area (EEA). It harmonises equipment regulations across this area.

Once equipment has undergone conformity testing to ensure it complies with the LVD, a CE mark can be affixed. This demonstrates that equipment meets the requirements of the LVD and can be sold or supplied across the European market.

The LVD is officially named the Directive 2014/35/EU of the European Parliament and of the Council of 26 February 2014.

-

Which equipment is covered by the LVD?

The LVD is designed to protect against health and safety risks presented by electrical equipment. It applies to equipment in the following voltage ranges for input or output:

- 50 and 1000 V for alternating current

- 75 and 1500 V for direct current

LVD concerns the majority of electrical equipment within the voltage brackets above. This includes equipment such as; appliances, cables, cable management systems, plugs and plug outlets, fuses, switches, power supply units and laser equipment.

-

What are the most important LVD responsibilities for manufacturers?

Manufacturers are responsible for ensuring that the design and production of electrical equipment comply with the LVD.

There are four key responsibilities outlined by the LVD:

- there should be minimum risk that the electrical equipment will cause death or personal injury to any person or domestic animal, or damage to property.

- constructed in accordance with good engineering practice in relation to safety matters.

- designed and constructed to ensure that it protects against electric shock through protective earthing, double insulation or equivalent.

- designed and constructed to conform with the principal elements of the safety objectives, which are in Schedule 3 of the regulations.

-

Who enforces the LVD?

In the EU and EEA, the LVD is enforced by national authorities and market surveillance authorities or their equivalent, while the European Commission coordinates enforcement and offers guidance.

The UK equivalent of the LVD - The Electrical Equipment (Safety) Regulations 1994 - are enforced by the Health and Safety Executive (HSE) when electrical equipment is used in industrial or commercial premises, and by the Trading Standards Service when electrical equipment is used in residential properties.

-

What are the penalties for non compliance with the LVD?

Manufacturers or distributors not complying with the LVD are committing an offence. They risk a fine, imprisonment, or both.

In the UK, the HSE can request the withdrawal of electrical equipment from the market if it is found to be non-compliant with the LVD.

What We Do

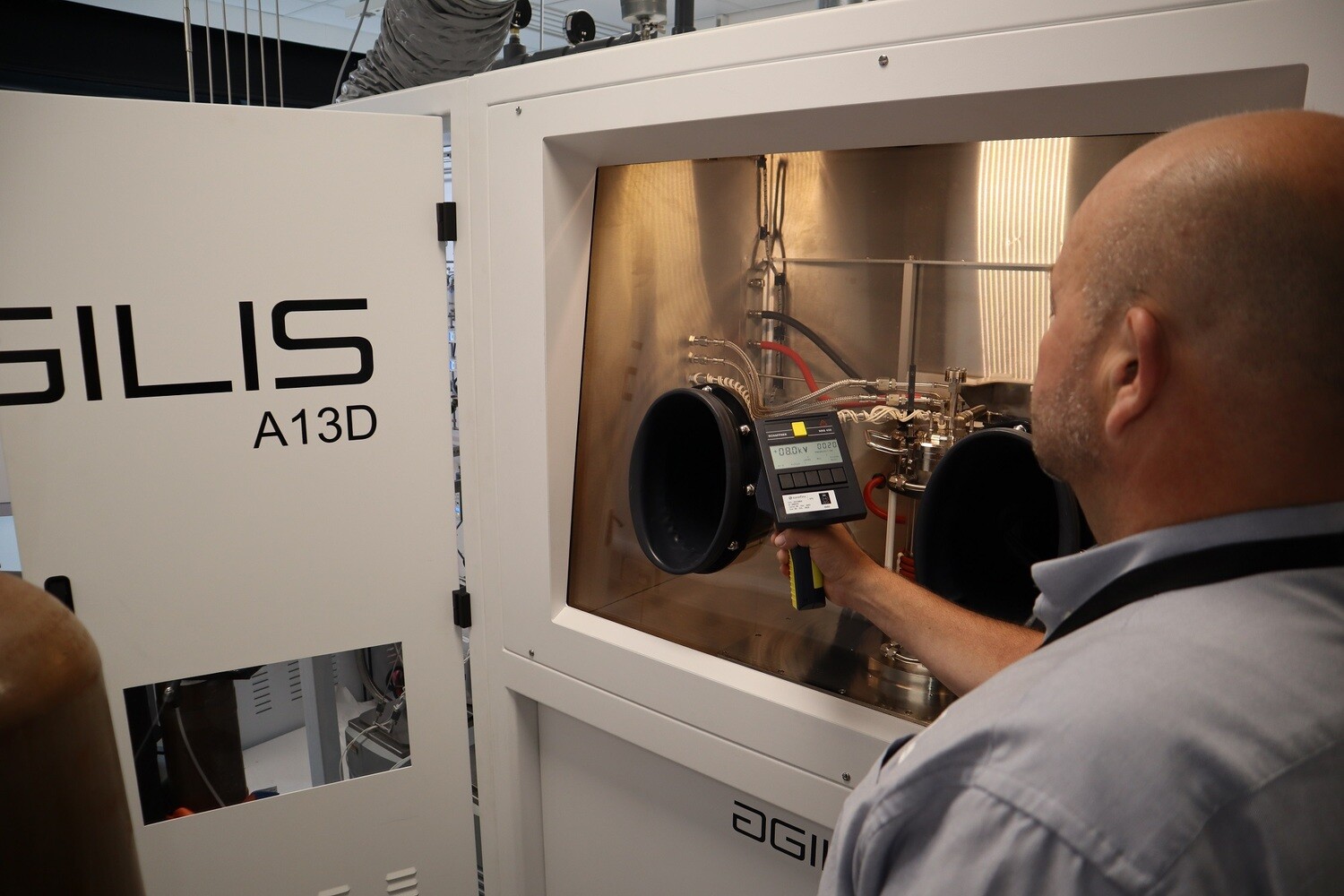

From electron microscopes to x-ray scanners, we help high-technology manufacturers and importers evaluate medium and large-sized electrical equipment against Electrical Equipment/LVD regulations and ensure compliance. Our start-to-finish service includes:

|

|

Electrical equipment product safety inspection (either on-site or at our Bristol facility) |

|

|

Evaluation of equipment and accompanying documentation against Electrical Equipment/LVD regulations |

|

|

Full written report of test data and any non-compliance issues |

|

|

Compilation of all technical documentation |

|

|

Consultancy and support throughout, including guidance on the most appropriate remedial actions, if required |

|

|

Additional services, if required:

|

Electrical Equipment (Safety) Regulations

Learn more about the Supply of Machinery (Safety) Regulations and what they cover.

Why Work With Us?

-

35+ Years of machinery expertise

Work with a partner that has more than three decades of experience working with high-technology capital machinery and equipment

-

Thorough checks for your peace of mind

Have total confidence that your machinery and equipment has been rigorously evaluated by a specialist team and ticks every box

-

Ongoing expert help & advice

Get an ongoing expert consultancy service, including personalised guidance on the most appropriate remedial actions in the event of non-compliance

-

Specialist support

Work with a team that’s always on hand to answer any questions you might have about your equipment or the project

Our Unique Capabilities

Equipment Expertise

We’ve been working with high-technology capital machinery and equipment since 1991.

On-site Testing

We travel to your UK site to perform your equipment evaluation, or you can come to our Bristol site if preferred.

End-to-end Support

Alongside testing, we can also support UKCA/CE marking, equipment relocations, export packing and more.

Trusted by Rolls-Royce, Analog Devices, University of Bristol and more

Since 1991, we’ve been helping manufacturers and importers in the semiconductor, pharma and other high-technology industries to evaluate high-technology machinery in cleanrooms, labs and production facilities across the UK.

How we helped the University of Bristol carry out Supply of Machinery (Safety) Regulations/Machinery Directive 2006/42/EC tests on their new metal organic chemical vapour deposition (MOCVD) machine, helping them achieve UKCA and CE compliance.

Speak with one of our experts

Request a callback from one of our team or book a site survey for your project.