The 4 Essential “P”s of Moving Pharmaceutical Equipment

The pharmaceutical sector is continuously evolving. And as facilities scale up production, reconfigure cleanrooms, or introduce new technologies, the...

We're actively recruiting for a range of roles across sales, engineering, IT and warehouse. Check our careers page to see open positions including apprenticeships.

At IES, we love a challenge. In fact, the more complex the project is, the better.

Few complex engineering projects compare to the challenge of relocating sensitive, high-technology equipment across borders.

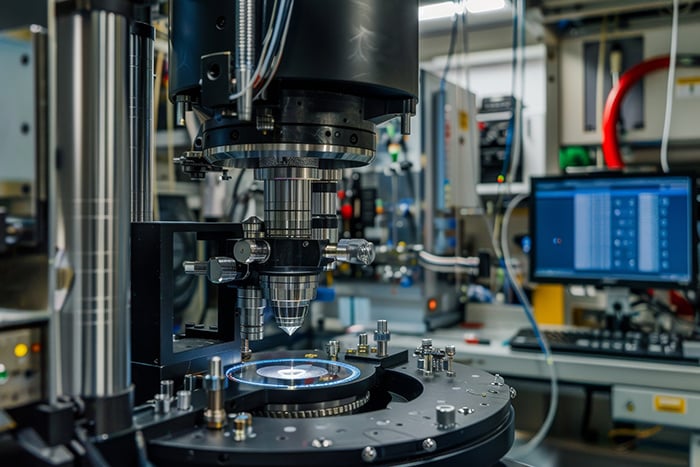

At IES, we partner with leading global manufacturers to provide an extensive portfolio of advanced technologies supporting research, development, and production across the semiconductor and compound materials industries.

Whether you’re moving a single piece of equipment or an entire production line, our trusted team of engineers can support every step of your move, from rigging to end-to-end relocation support across the globe.

5 min read

Admin Updated on August 1, 2025

Planning a complex capital equipment relocation and looking for the right partner to support the project?

.jpg?width=810&height=581&name=Equipment%20Moves%20-%20Vista%20Engineering%20Cleanroom%20(5).jpg)

Selecting the right partner requires significant research into their expertise, past projects and additional support services. As well as whether they’re equipped to handle any special requirements you might have—for example, operating in cleanroom manufacturing environments.

From experience, process, logistics and timelines to safety, insurance and post-move support, here are seven things you should ask your chosen relocation partner about before starting your project, as well as a few example questions to get started.

Experience matters when it comes to moving complex capital equipment.

You’ll want to not only ascertain whether your selected partner has experience working with your specific type of tool, manufacturer and working environment, but also whether they have the expertise to handle any complexities and challenges that might arise during the project.

As such, you’ll want to ask about past projects they’ve been involved in, any training and special skills their teams possess and their experience working in specialist environments such as cleanrooms, if applicable.

Example questions:

A successful relocation hinges on strong teamwork between your internal teams and your partner.

Understanding your potential partner’s planning, coordination and execution processes will help you not only anticipate what you should expect from them throughout the project, but also whether the way they work aligns with the way your teams work and how you can collaborate more effectively.

You’ll also want to understand how your potential partner approaches planning the project, for example, how they approach facility inspections and planning to minimise downtime. This is so you can feel confident that your partner will take all your requirements into account.

Example questions:

Large, delicate and complex capital equipment can be easily damaged during transit if packed inadequately or handled incorrectly.

As such, it requires special handling and packing to protect it against vibrations, shock and other environmental impacts.

Seek to understand not only how your potential partner disassembles and packs equipment to protect it against damage, but also how it ensures safe handling during transit.

As part of this, you’ll want to ask about the equipment, resources and vehicles they use, how they handle traceability and whether they have experience packing and handling hazardous or sensitive components if applicable.

Example questions:

Timelines are a useful tool for estimating your project’s overall length and key milestones. But they aren’t set in stone.

Knowing as much as possible upfront about the estimated project timeline and how it could potentially change over the course of the project allows you to plan accordingly on your end and manage your expectations regarding downtime.

As part of that, you’ll want to understand how long each stage of the project is likely to take (including disassembly, packing, shipping, unpacking and move-in), so you can estimate the level of disruption this might cause to your operation and how you can mitigate it.

You’ll also want to hear from your supplier about how they handle challenges and unforeseen delays that arise throughout and keep the project on track.

Example questions:

A great partner can not only successfully relocate equipment from point A to point B. They also have the know-how to protect your equipment and personnel during the process, while adhering to the most stringent regulatory compliance requirements.

Ensure that your potential partner has the proper safety protocols in place, the relevant certifications and training and the right protocols and practices to protect your equipment and people against harm, and your business against fines for non-compliance.

Example questions:

It doesn’t happen often, but it does happen: relocations can go wrong.

And, when they do, you want peace of mind that you’re fully covered for the costs of repairing damages to equipment, replacing lost equipment or any accidents.

Ask your potential partner for details about their existing insurance coverage and what’s covered, so you can feel confident that you’re financially protected throughout the move. You’ll also want to understand which areas you would be liable to carry out additional insurance for.

Example questions:

Your project doesn’t just end when your tool reaches its final destination.

![]()

Depending on your in-house resources and expertise, you might need additional support with equipment installation, calibration, testing and start-up.

It’s essential to check in advance whether your potential partner offers this post-move support as part of their offering if needed. You’ll also want to check what the support includes, whether it fits your specific requirements and any additional costs that it might involve.

Example questions:

At IES, we can handle every single part of your equipment relocation, from de-installation, packing and transport to installation, build and start-up.

So, whether you’re relocating single pieces of equipment and production lines or complete manufacturing facilities, just tell us what you need and we’ll handle the rest.

Stay up to date with the latest news and resources from our experts.

The pharmaceutical sector is continuously evolving. And as facilities scale up production, reconfigure cleanrooms, or introduce new technologies, the...

Moving complex pharma equipment and systems into your lab is not your everyday project.

Whether you’re moving sensitive instruments like electron microscopes and spectrometers or high-powered lasers and centrifuges, relocating lab...