A Complex Intercontinental Move and Assembly Project for Multiple Ion Implanters

At IES, we love a challenge. In fact, the more complex the project is, the better.

We're actively recruiting for a range of roles across sales, engineering, IT and warehouse. Check our careers page to see open positions including apprenticeships.

At IES, we love a challenge. In fact, the more complex the project is, the better.

Few complex engineering projects compare to the challenge of relocating sensitive, high-technology equipment across borders.

At IES, we partner with leading global manufacturers to provide an extensive portfolio of advanced technologies supporting research, development, and production across the semiconductor and compound materials industries.

Whether you’re moving a single piece of equipment or an entire production line, our trusted team of engineers can support every step of your move, from rigging to end-to-end relocation support across the globe.

3 min read

Admin Updated on February 25, 2026

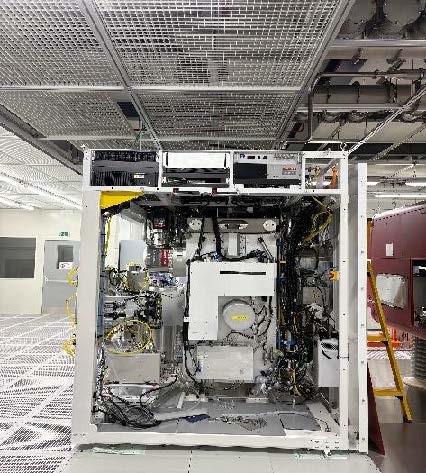

One of our long-standing partners, whom we've worked with since 1997, recently contracted us to deinstall an Axcelis Purion ion implanter from their controlled cleanroom facility and pack it for transport.

Dismantling the tool would mean carefully separating interconnected assemblies, safely rigging them out of the building, and ensuring every component (from graphite elements to fibre-optic cables) was protected for transport.

Our team of engineers had five days to complete the deinstallation and pack all components and assemblies for international shipping.

Here's how we tackled it.

We started by methodically labelling and removing all the external panels, doors and components. Each exterior panel came off carefully, with interlocks disconnected and staged on plastic pallets.

With the outer shell removed, we could see the internal LED shielding and lighting arrays. These came out next, along with all the grounding connections.

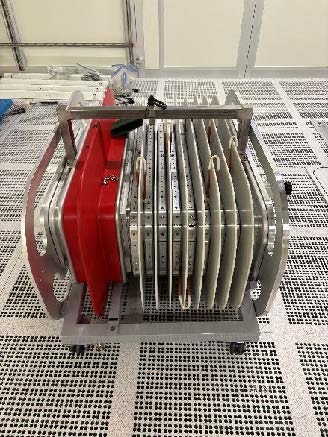

Then, we removed the graphite from both the process chamber and the acceleration column, placing each on a cart with a protective covering.

Before we finished for the day, we disconnected the Very Early Smoke Detection Apparatus (VESDA) and removed the emergency shut-off panels. By the end of day one, the tool was opened up and ready for the real work to begin.

Day two, we focused on cabling and pipework disconnection and separation.

We started with the utilities. Gas lines and deionised (DI) water connections between the terminal, motor generator and facilities assemblies all had to be carefully disconnected. Then came the power cables, fibre-optic lines, and data connections running from the process assembly to the power distribution unit.

Before we could touch anything else, we needed to isolate and safely remove the resistor assembly, bleeder bar, shorting bar and RP1 unit.

With the high-voltage systems safely isolated, we moved on to the mechanical connections. The shaft assembly, cover, DI feedthrough and the main power distribution (PD) anaconda cables all had to be carefully removed. We finished by disconnecting the equipment front-end module (EFEM).

We were making good progress, but still had a way to go.

By day three, we were working our way upward. The tool’s roof structure and overhead infrastructure needed to be removed before we could move the major assemblies out of the cleanroom.

We started by disconnecting the final electrical connections and removing all remaining grounding tags.

Then came the overhead work. The ceiling-mounted exhaust units had to be carefully lowered and removed, followed by the cable trays. Finally, we labelled and removed the ceiling panels themselves, opening up the space above the tool.

We could then remove the resistor stack and high-voltage stack.

By the end of day three, we'd achieved full mechanical and electrical isolation. Every assembly was now separate, every connection was documented, and every component was accounted for.

We gathered the team to confirm our rigging plan for the next day and walked through the egress routes.

With the tool fully dismantled, the roof's I-Beam structure came down first on day four. We removed two I-beams and all the supporting trusses from the ceiling.

Then came the critical work: separating the EFEM from the process assembly. Once apart, we fitted both assemblies with wheels and transport brackets, effectively converting them into moveable units.

We removed the process assembly wall extension next, and fitted the facilities assembly with transport brackets and wheels, ready for movement. All the major assemblies were then carefully moved onto slip paper.

The last task was handling the anaconda bundles from the remote facilities. We coiled them up, securing each bundle and preparing them for transport.

By the end of the day, everything was staged and ready. Tomorrow will be moving day.

The final day arrived.

Rigging went smoothly. One by one, each assembly was carefully manoeuvred through the cleanroom, out through the designated egress routes, and into the packing area. Our team worked together and stayed in constant communication, coordinating every move.

Once in the packing area, we began the multi-layer protection process. Each assembly was wrapped in polythene first, then bubble wrap for cushioning, and finally vacuum-sealed in foil bags to protect against moisture and contamination during shipping.

We secured each unit on a base with timber bracing to prevent any internal movement and used cord straps to lock it all in place.

Then came the crating. Each assembly was fitted into custom crates, metal-banded for security during the long journey ahead. We added inspection holes to each crate, a small but important detail to allow customs officials to verify contents without having to open the protective packaging and potentially expose the equipment.

As the sun set on day five, we loaded the final crate onto a MEGA trailer. The entire Purion ion implanter, including its assemblies and components, was ready for transport.

The tool would arrive at its destination in the same condition it left protected, organised and ready for reinstallation.

We've been supporting semiconductor OEMs and end users to move, deinstall and pack complex ion implanters and other critical equipment since 1991.

From single tool moves to complete cleanroom relocations, our team of specialist engineers can support every step of your project.

Learn more about our semiconductor tool services here.

Stay up to date with the latest news and resources from our experts.

At IES, we love a challenge. In fact, the more complex the project is, the better.

Plessey Semiconductors is a long-established electronics company, currently at the forefront of microLED display technology for AR/MR applications ...

Ever installed a 12m-long press through a third-storey window? We have.