Relocating 7 precision laser cutters for Wentworth Wooden Puzzles

Based in the heart of the Wiltshire countryside, Wentworth Wooden Puzzles is renowned for its intricately crafted wooden jigsaw puzzles, each cut and...

We're actively recruiting for a range of roles across sales, engineering, IT and warehouse. Check our careers page to see open positions including apprenticeships.

Whether you’re moving a single piece of equipment or an entire production line, our trusted team of engineers can support every step of your move, from rigging to end-to-end relocation support across the globe.

AB Dynamics is one of the world’s leading suppliers of automotive test systems. From their origins nearly four decades ago as an automotive engineering consultancy, they now count all of the world’s 25 biggest car makers among their customers.

As the business continued to grow and headcount doubled in just four years, they needed more space to support the increasing demand for their cutting-edge robotics, ADAS targets and automotive testing equipment.

The solution was a brand-new Engineering Design Centre, built adjacent to their existing site in Bradford-on-Avon.

As part of the move-in to this new purpose-built facility, they’d need to relocate 15 pieces of critical equipment and several ancillary items, and with zero downtime.

They needed a partner they could trust to execute the move safely and efficiently.

We’ve worked with AB Dynamics for over 15 years and are incredibly familiar with their equipment and its handling needs.

So when it came time to relocate key operational assets into the new facility, AB Dynamics called upon us to get the job done.

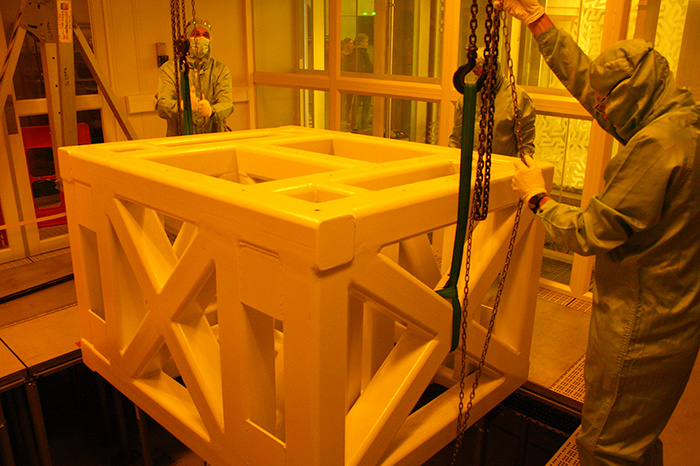

Moving large, high-precision equipment is no simple task. Even a minor knock or misalignment can cause significant disruption. Not just in downtime, but in costly repair and recalibration.

This particular relocation involved a total equipment weight of 20 tonnes, adding further complexity to the project.

But we were well-prepared for the task.

Our team has extensive experience with factory relocations and regularly supports AB Dynamics with the packing and transport of their 17-tonne Suspension Parameter Measurement Platforms (SPMMs), a specialist vehicle Kinematics and Compliance (K&C) test system used by leading suspension engineers worldwide.

For this move, the equipment list included:

The move also involved CNC machining centres weighing 4.2 tonnes and 2.6 tonnes respectively. These units occupied 13 ft x 9 ft and 5 ft x 9 ft of floor space and were essential to all prototype and development work for AB Dynamics’ projects.

Given their critical importance, it was vital they were moved and reinstalled safely, with pinpoint precision.

An IES electrician supported the disconnection process to ensure each unit was safely powered down and ready for transport.

One key challenge uncovered during our pre-move site inspection was access.

The main road leading to the Holt Road site entrance had a tight turning space and led onto a steep slope. This was far from ideal for moving multi-tonne equipment.

To mitigate risk, we allocated an experienced driver capable of manoeuvring with precision in tight spaces and selected vehicles that could handle the equipment load without grounding out on the slope.

We also supplied forklifts and lifting equipment to raise the equipment onto timber bearers for stable loading onto flatbeds and 18-tonne curtain-sided trucks.

The relocation took place over five days, with our team overseeing every element of the project.

From disconnection and lifting to transport, offload and repositioning, our team ensured each item was safely and efficiently moved.

Careful planning and sequencing gave us ample room to manoeuvre equipment into its final position within the new facility.

Thanks to careful project management, specialist handling and close communication, AB Dynamics’ critical equipment stayed in the hands of a single trusted supplier, from disconnection to reinstallation.

The result? Reduced risk, better efficiency and a project delivered on schedule and to a high standard.

Here’s what the UK Facilities Maintenance Manager at AB Dynamics had to say about working with us:

“Fifteen years working with the same partner means they understand our business and what we need. And when you’ve grown as quickly as we have, this shorthand understanding enables equipment moves to be carried out with the minimum of fuss.

“They know AB Dynamics, and we’ve always been happy with their work. If we have any issues, they’re always there to support, which is exactly what we look for in a partner. It has been a significant benefit for our business to have this level of continuity and partnership with IES.”

For more than 30 years, we’ve been helping OEMs and end-users in the microelectronics, semiconductor, pharmaceutical and other high-technology industries to relocate business-critical equipment in cleanrooms, labs and production facilities all across the globe.Find out more about our turnkey relocations service here.

Stay up to date with the latest news and resources from our experts.

Based in the heart of the Wiltshire countryside, Wentworth Wooden Puzzles is renowned for its intricately crafted wooden jigsaw puzzles, each cut and...

One of our long-standing partners, whom we've worked with since 1997, recently contracted us to deinstall an Axcelis Purion ion implanter from their...

The University of Southampton is a world leader in photonics and optoelectronics.