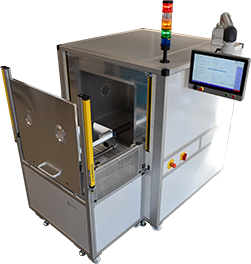

AL235

The Alpha Plasma System AL 235 is a robust, high-capacity aluminum-chamber plasma solution designed for enhanced ergonomics and automation in demanding R&D and production environments. It elevates the AL-series by integrating features that simplify sample handling and processing, making it ideal for medium-to-large format applications across industries like semiconductors, electronics, solar, and plastics.

Key Features:

Automated Door System

- Incorporates a motorised or automated door mechanism for more efficient, safe, and user-friendly loading and unloading of substrates.

Adjustable Work Height

- Designed with an adjustable working surface to accommodate operators of varying heights and reduce repetitive strain, improving ergonomics and workflow.

Large-Scale Processing Capability

- Builds on the AL-series’ reputation for handling larger substrate sizes, leveraging aluminum chamber construction for durability and effective process control.

Technical Data:

- Dimensions: L: 1200mm W: 2700mm H: 1850mm

- Weight: 380 KG

- Volume: 235 Liter

- Process chamber: L: 650 W: 650 H: 550

- Microwave output: 2,45 GHz / 1200 and 1450 Watt

- Inclusive: 1 gas channel (gas distribution system inside the process chamber), up to 3 channels available

- Substrate holder (optional): aluminium, custom design possible

- Vacuum connection: DN 100 ISO-K

- Venting: electromagnetic solenoid valve

- Pump system: 50 -600 m³/h process-dependent

- Chamber door: Automatic door

Applications:

- Semiconductor / wafer processing / packaging – for wafers, modules or maybe large substrates needing plasma treatment. The AL series is explicitly targeted at semiconductor/solar/plastics/electronics industries.

- Electronics / PCBs / module manufacturing – larger boards or modules (e.g., for IoT, automotive electronics) needing surface prep/coating.

- Solar / photovoltaics – large flat substrates, cleaning/activation of solar cell modules or components prior to assembly or coating. The AL‐series mention solar in their brochure.

- Plastics / polymer components – when you have larger plastic parts or assemblies that need plasma-treatment (cleaning, activation) before coating or bonding.

- Automotive / aerospace components – When there are large parts (sensor modules, assemblies) requiring good surface condition before protective coatings or bonding. The automatic door and larger chamber make it more compatible with such applications.

- Medical / harsh‐environment coatings – If you have moderate to large size parts requiring ultra-clean surfaces or special coatings (e.g., conformal coatings, parylene) then this system is a good fit.

Book a Live or Virtual Demo

See the capabilities of our partners' equipment - including EVG, scia Systems, Veeco, PPS and SSI - in action. Experience tailored demonstrations designed around your process and application needs.