Why Are RAMS So Essential for Lab Equipment Movers?

Whether you’re moving sensitive instruments like electron microscopes and spectrometers or high-powered lasers and centrifuges, relocating lab...

We're actively recruiting for a range of roles across sales, engineering, IT and warehouse. Check our careers page to see open positions including apprenticeships.

At IES, we love a challenge. In fact, the more complex the project is, the better.

Few complex engineering projects compare to the challenge of relocating sensitive, high-technology equipment across borders.

At IES, we partner with leading global manufacturers to provide an extensive portfolio of advanced technologies supporting research, development, and production across the semiconductor and compound materials industries.

Whether you’re moving a single piece of equipment or an entire production line, our trusted team of engineers can support every step of your move, from rigging to end-to-end relocation support across the globe.

3 min read

Admin Updated on February 12, 2026

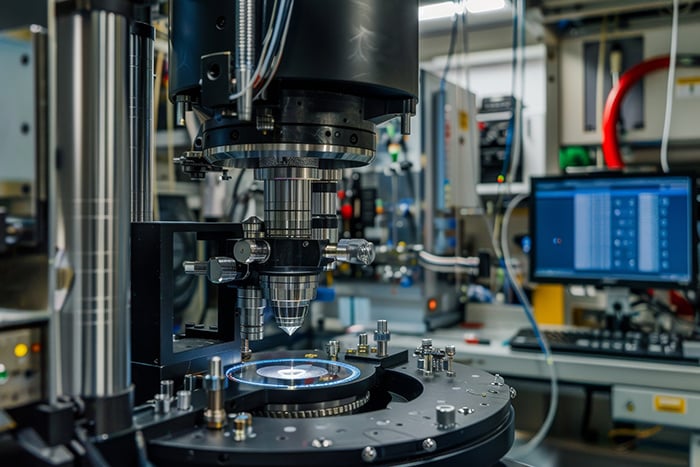

Whether you’re transporting high-value equipment within a cleanroom environment, positioning delicate scientific instruments, or aligning heavy tools, traditional moving skates often lack the level of precision, accuracy and care that you need.

Air skates (also known as air casters) are redefining how engineers handle complex equipment moves. By lifting heavy loads on a controlled cushion of air, they provide a friction-free, highly accurate way to manoeuvre delicate tools safely.

In this guide, we break down how air skates work, their key advantages, the common challenges, and why they’re becoming a vital technology for high-precision equipment relocations.

Conventional moving skates are designed to carry heavy loads. But they’re not the best choice for moving more sensitive, high-technology, precision equipment (for example, scanning electron microscopes).

Their limitations include:

Wheeled skates create unavoidable friction and vibration. For delicate tools, even minor shock loads or floor imperfections can compromise alignment or functionality.

Traditional skates are often one-directional and require steering mechanisms and repositioning efforts just to help them change direction, slwong down your move.

Because removal routes are often indirect, that means you’ll likely have to remove or shut down any pieces of equipment that are in the way, causing cascading delays for production and significantly impacting your bottom line.

For controlled, low-impact movement, you need a more advanced solution.

Air skates create a thin cushion of air between the load and the ground.

This acts as a lubricating layer, reducing friction and allowing the load to “float” slightly above the ground (similarly to how a puck floats on an air hockey table, but in a much more engineered and industrial form).

Here’s how it works:

The result is a level of precision and control that traditional systems simply cannot achieve.

Air skates allow equipment to move effortlessly in any direction (forward, backward, sideways or diagonally) without needing to reposition the system. And with exceptional control.

Operators can control movement by adjusting air pressure, making alignment tasks simpler and far more accurate.

This also allows teams to navigate around obstacles rather than removing other tools, saving time and preventing disruption.

Because equipment floats on a cushion of air, it avoids the harsh mechanical contact associated with wheels or rollers.

This greatly reduces the risk of:

For environments where precision is essential, this is a major advantage.

Traditional skates concentrate weight on a handful of rollers. Air skates distribute the load evenly across all air pads, reducing:

This makes them ideal for delicate floors, cleanroom environments and heavy-duty equipment moves.

Air skates reduce manual pushing force dramatically. For example, just 5 kg of force can move a 1-tonne load.

This minimises risk of strains, slips or injuries, reduces reliance on large lifting equipment, and makes manoeuvring much safer in confined spaces or cleanrooms.

Even with their huge benefits, air skates must be used correctly and under the right conditions. Here are the main factors to assess.

Air skates perform best on flat surfaces. Even small inclines can cause loads to drift or roll, creating safety hazards.

Best practice:

While air skates can traverse small cracks or expansion joints, larger voids may cause the air skates to drop and stick.

Best practice:

The air cushions rely on a reinforced diaphragm. Sharp debris, loose screws or surface hazards can puncture or rupture the bladder, causing loss of lift, sudden tool drops and unforeseen safety risks.

Best practice:

Need to move sensitive, business-critical equipment? Put your trust in our team of expert engineers and movers.

We’ve been moving sensitive equipment since 1991, working with businesses in high-technology industries like semiconductor, pharmaceutical and aerospace.

Stay up to date with the latest news and resources from our experts.

Whether you’re moving sensitive instruments like electron microscopes and spectrometers or high-powered lasers and centrifuges, relocating lab...

An ‘end-to-end’ provider means the supplier of a solution which encompasses an operation from start to finish.

Moving and installing high-technology equipment is always a challenging task, but when you add a cleanroom environment to the mix, things get even...