Your UKCA Marking FAQs, Answered

Before you can sell or supply certain products in Great Britain, you must certify that they comply...

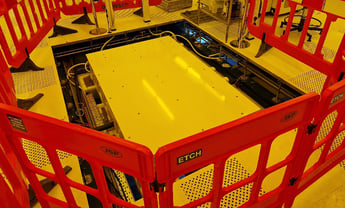

Maximising Semiconductor Equipment Uptime: 5 Key Maintenance Tips

In semiconductor manufacturing, even brief equipment downtime can have serious consequences, from...

From the classroom to the cleanroom: Harri's career-shaping apprenticeship journey

Apprenticeships have traditionally been seen as an alternative to university. But, in reality, they...

9 Benefits of Working with a Field Service Engineer (FSE)

When you’re working in a fast-paced, high-technology environment, having easy access to highly...

Best Practices for Decontaminating an Ion Implanter for Removal

If you’re moving or relocating an ion implanter - particularly one that’s been in use for an...

Why Are RAMS So Essential for Lab Equipment Movers?

Whether you’re moving sensitive instruments like electron microscopes and spectrometers or...

7 Key Considerations for PUWER Compliance in Manufacturing

As a manufacturer, if you own, operate or control any kind of mechanised work equipment (including...

Importing High-Technology Capital Equipment: What Documentation Do You Need?

Looking to import high-technology capital equipment into the UK from a country outside of the UK...

Key Considerations for Moving and Installing Cleanroom Equipment

Moving and installing high-technology equipment is always a challenging task, but when you add a...

How To Design a Wooden Crate for Capital Equipment

When transporting delicate, high-technology and high-value capital equipment, the right wooden...

UKCA Marking Production Lines: What Should Your Technical File Contain?

Planning to combine a series of complete or partly completed machines to create a single production...

Commissioning High-Technology Capital Equipment: An Expert’s Guide

You’ve spent the past few weeks relocating, installing and setting up a piece of high-technology...

Making Impossible Possible: Life of a Travelling Installation Engineer

Installation engineers, like me, experience life in a very unique way.

7 Considerations When Moving Complex Pharma Equipment into Your Lab

Moving complex pharma equipment and systems into your lab is not your everyday project.

UKCA Vs CE Marking: What’s the Difference?

Product marking is crucial for retaining market access, adhering to local legal requirements and...

How To Design and Install a Structural Machine Base

Using a well-made structural machine base versus a substandard base can be a matter of life or...

Importing Capital Equipment: Complying with UKCA Marking

Many manufacturers require the importation of mechanical, electrical, and electronic manufacturing...

What To Ask Your Capital Equipment Relocation Partner Before Starting a Project

Planning a complex capital equipment relocation and looking for the right partner to support the...

What are the SEMI Packing Standards?

How a semiconductor tool is packed directly influences its long-term performance, longevity and...

4 Expert Tips for Export Packing Semiconductor Equipment

We’ve worked with complex, business-critical semiconductor equipment since 1991. And in that time,...

How to Achieve UKCA Compliance in 5 Steps

Are you a manufacturer looking to supply a product, equipment or piece of machinery to markets in...

How Air Skates Are Supporting the Way We Handle Precision Movement

Whether you’re transporting high-value equipment within a cleanroom environment, positioning...

What is ISPM 15? And Who Does it Apply To?

The International Standards for Phytosanitary Measures Publication No. 15 are commonly known as...

How IES FSEs Support Fabs to Keep Tools Running

Semiconductor fabs thrive on optimisation. From minimising downtime to increasing the lifespan of...

6 Things to Consider When Planning an Equipment Relocation Project

It doesn’t matter whether you’re only moving a single piece of equipment to a different area of...

High-Technology Equipment Decommissioning: How to Get it Right

Before you can move or pack high-technology equipment for relocation, you first need to...

The 4Ps of moving pharmaceutical equipment

The pharmaceutical industry is growing and evolving. Consumer spending on pharmaceutical products...

How to Handle Freight Forwarding During a Supply Chain Crisis

We are currently experiencing a global supply chain crisis. Delays and shortages are causing a...

Machinery movement insurance: Getting the right cover

Are you planning to move a piece of hi-tech equipment, a complete production line, or an entire...

IES Furthers Apprenticeship Scheme Commitment

We have decided to roll out the IES apprenticeship scheme, recruiting for two new roles that offer...

Do's and Don’ts of ISPM 15

ISPM 15 are the standards which provide criteria for regulating wood as a packaging material.

How to Rig Machinery

Rigging is an integral part of equipment moves – in fact, without rigging there would be no...

ISPM15 and Heat Treated Export Packing Solutions - A Guide

ISPM15 standards provide the criteria for wood used as packaging material. They are intended to...

A Guide to Our Custom-Made Wooden Crates

When you’re shipping sensitive, high-value, business-critical equipment, you need total peace of...

Why to Use an End-to-End Provider for Machine Relocation

An ‘end-to-end’ provider means the supplier of a solution which encompasses an operation from start...

Harri is Learning More as an Engineering Apprentice

After leaving school, Harri Green started a full-time college course. But a few months later he...

Cross-Training and Beyond – Building Employee Experience

When you consider the wide range of services that IES offers its clients, you may think we have...

Why Quality Export Packing is Vital For International Trading

Global trade is the lifeblood of a growing number of companies. According to a 2023 report from the...

The Power of Apprenticeships

School leavers are often inundated with options for their future. Should they choose higher...

Bespoke Packaging for Large Machinery: Breaking Down the Build

IES has almost three decades’ worth of experience in packing and shipping machinery, ranging from...

Who’s Who in Your Factory Relocation Project?

Relocating a factory is a bit like building a machine; all the cogs need to fit and work together....

Our 6-Step Process for Equipment Transport

Transporting complex, high-technology equipment is no easy feat—regardless of whether you’re an OEM...

Specialist Engineer Brian Fletcher’s 5 Expert Tips for Factory De-installations

Factory de-installations are never simple. But they’re a lot easier when you do them right.

Packing High-Technology Equipment: An Expert’s Guide

It doesn’t matter if you’re moving a piece of high-technology equipment 20 miles across towns or...

Factory Relocation: Method Statements and Risk Assessments

Relocating an entire factory is no small feat. Much like the workings of the factory itself, it...

Customs and Shipping for Global Factory Relocations: What You Need to Know

Relocating a factory is no easy feat.

How to Carry Out a Site Survey for Your Manufacturing Facility Relocation

You might’ve heard the phrase: If you have six hours to chop a tree, you should spend the first...

Semiconductor Equipment and Process Training from IES

IES offers a variety of courses that cover a wide range of topics central to the semiconductor...

EMF in Manufacturing Environments: Why it Matters

If you operate a manufacturing site that uses high current or high voltage applications,...

When Do I Need PUWER?

Health and safety is awash with acronyms; so much so that it can be easy to get confused sometimes....

Export Packing Essentials: Key Considerations

With over 30 years of experience in projects of all shapes and sizes, for clients representing...

8 Tips to Relocate High-Value Equipment Like an Expert

Factory relocations are high-stakes projects.

5 Key Areas for Smooth Packing Process

At IES we have been involved with equipment and machinery packing in many industries for over 20...

How to Build a Wooden Crate

We’re often asked how we go about putting a bespoke packing case together and how long it takes. On...

How to Achieve CE Compliance in 5 Steps

Conformité Européenne (CE) marking is the European Union’s required certification for products,...

Which Products, Equipment and Machinery Need CE Marking?

Before you can sell or supply certain products, equipment and machinery in the European Economic...

From ISPM to UKTR: Understanding Wooden Packaging Laws for Global Shipping

Shipping sensitive items internationally?