- Equipment Partners

- Products

- Plasma Parylene Systems (PPS)

- Parylene Coating

- Series 3000 LV 800/1000

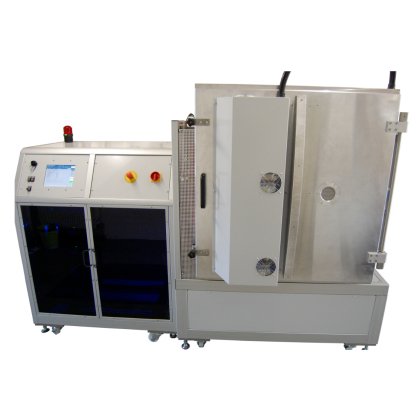

Series 3000 LV 800/1000

The Series 3000 LV 800/1000 is a modular parylene coating system designed for high-throughput applications. It features a two-part configuration, comprising a chamber module and an evaporator module, allowing for flexible setup and maintenance. With chamber volumes of 800 or 1000 liters and a 2.45 GHz, 1200 W plasma source, it ensures uniform coating and surface treatment. Additional features include an 8-liter cooling system, 75 m³/h pump capacity, and multiple gas channels for enhanced process control. This system is ideal for applications requiring large-scale, consistent coating quality.

Key Features:

- Modular Design with Separate Functional Units Engineered as a two-part system—comprising distinct chamber and evaporator modules—this design enhances flexibility, simplifies maintenance, and supports scalable integration.

- High-Volume Processing Capacity Equipped for significant throughput, this system accommodates 800 L or 1,000 L chamber volumes:

- 800 L version: chamber diameter 1,150 mm, height 600 mm

- 1,000 L version: chamber diameter 1,000 mm, height 1,100 mm

- Substantial Physical Footprint & Robust Construction

- Overall Dimensions: Length 2,600 mm × Width 960 mm × Height 1,460 mm

- Weight: Approximately 450 kg

- Integrated High-Power Plasma Activation Features a built-in 2.45 GHz, 1,200 W plasma source, enabling effective surface activation and pre-treatment for improved coating adhesion.

- Flexible Gas Distribution System Includes one internal gas channel, with the option to expand up to three channels to support multi-gas or layered coating processes.

- Advanced Cooling & Condensation Control Utilizes an 8-liter electromechanical cool-trap to manage condensation efficiently and maintain thermal stability during operation.

- Reliable Vacuum & Venting Infrastructure

- Vacuum Interface: DIN 63 ISO-KF standard connection

- Standard Industrial Electrical Integration Power Supply: 3-phase (3/N/PE) AC at 50 Hz, compatible with 400 V or 240 V systems

- Max Power Consumption: 8.5 kW

Technical Data:

- Dimensions: L: 2600mm W: 960 H: 1460mm

- Weight: ~ 450 KG

- Volume: 800 / 1000 litres

- Process chamber: 1150mm Ø H: 600mm (800 Liter), 1000mm Ø H: 1100

- Plasma source: 2,45GHz, 1200 Watt

- Inclusive: 1 gas channel (gas distribution system inside the process chamber), up to 3 channels possible

- Cooling system: 8 liter (electromechanical Cool-trap)

- Vacuum connection: DIN 63 ISO-KF

- Venting: electromagnetic solenoid valve

- Pump system: 75m³/h

- Electrical connection: 3/N/PE AC 50Hz 400 V / 240 V, max. 8.5 KW

Applications:

- Large-Scale / High-Volume Electronics Manufacturing Coating large assemblies, or very many smaller assemblies, in a single batch to increase throughput. High-reliability PCBs, sensor modules, RF / microwave components where parylene gives excellent moisture, chemical, and dust protection.Particularly useful for manufacturers scaling up from prototyping to mass production.

- Aerospace & Defense Avionics, satellite components, or other mission-critical electronics that need extremely reliable, uniform, pinhole-free coatings. With the plasma activation, adhesion is very good — important for vibration, temperature cycling, and reliability in harsh environments. Parylene’s low outgassing may be valuable in space / vacuum applications.

- Automotive / EV Applications High-throughput coating of control electronics, battery management modules, ADAS sensors, and ECUs. Protecting high-voltage and sensitive electronics from under-hood chemicals, moisture, salt etc. For EVs, parylene can help with insulation and protection in power electronics and sensor modules.

- Industrial / Harsh-Environment Sensing Sensors used in chemical plants, oil & gas, petrochemical, or process industries: the parylene barrier helps protect from corrosive or humid environments. Control electronics for industrial automation that must survive long-term in tough conditions.

- Medical Devices at Scale Implantable devices, medical sensors, or MEMS devices that need biocompatible coatings. High-volume production of medical components where conformal, pinhole-free parylene is required. Components that undergo sterilisation: parylene can form a robust barrier.

- Optoelectronics / Photonic Devices Large or many optical components, e.g., LED arrays, sensors, micro-optical elements, requiring a very uniform, transparent protective layer. Parylene is good for dielectric protection while being optically “invisible” at thin thicknesses.

- Micro / Nano Structures or MEMS at Pilot / Production Scale Research groups or companies scaling up micro- or nano-devices (MEMS, microfluidics) into production — the large chamber means they can do more in each batch. Coating of microstructures, microfluidic channels, or very intricate devices that benefit from parylene’s conformality.

Book a Live or Virtual Demo

See the capabilities of our partners' equipment - including EVG, scia Systems, Veeco, PPS and SSI - in action. Experience tailored demonstrations designed around your process and application needs.