- Equipment Partners

- Products

- Plasma Parylene Systems (PPS)

- Parylene Coating

- Series 3000 Cleanroom System

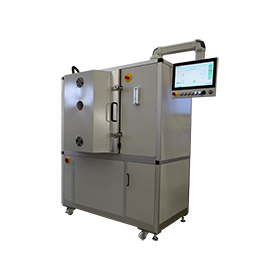

Series 3000 Cleanroom System

With modular assembly and variable chamber sizes, this system adapts seamlessly to your process needs. A wide range of options—such as turntables and specialised substrate holders—offers maximum versatility. Designed for cleanroom environments, it enables loading from the cleanroom and unloading via an airlock door into the gray room for efficient, contamination-free workflows.

Key Features:

- Cleanroom-Ready Design for Controlled Environments Specifically engineered for applications that must adhere to stringent cleanliness standards, this system ensures compatibility with cleanroom protocols and contamination-sensitive processes.

- Modular System Architecture with Customizable Chamber Sizes Featuring a modular assembly, the Cleanroom System offers flexibility in chamber configuration—supporting tailored volume requirements and seamless integration within production lines.

- Comprehensive Customization Options Designed to accommodate a variety of operational needs, the series supports numerous add-ons such as turntables, different chamber geometries, and other bespoke modifications to align with specific coating workflows. In-House Design & Manufacturing for High-Quality Assurance Plasma Parylene Systems develops both hardware and coating processes entirely in-house, enabling precise customisation and consistent quality from system design to execution.

Technical Data:

- Dimensions: L: 2095mm W: 800 H: 1450mm

- Weight: ~ 300 KG

- Volume: 140 / 200 / 300 / 800 litres

- Process chamber: 500mm Ø H: 700mm (140 Liter), 600mm Ø / H: 700mm (200 Liter), 700mm Ø, H: 800mm (300 Liter)

- Plasma source: 2,45GHz, 1200 Watt

- Inclusive: 1 gas channel (gas distribution system inside the process chamber), up to 3 channels possible

- Cooling system: 8 liter (electromechanical Cool-trap)

- Vacuum connection: DIN 40 ISO-KF

- Venting: electromagnetic solenoid valve

- Pump system: 75m³/h

- Electrical connection: 3/N/PE AC 50Hz 400 V / 240 V, max. 8.5 KW

Applications:

- High-Volume Electronics Manufacturing Large or many printed circuit boards (PCBs), assemblies, sensor modules. Parylene provides conformal protection (moisture, dust, ionic contamination). High reliability electronics (e.g. in telecom, industrial automation) where uniform, pinhole-free coverage matters.

- Aerospace & Defense Avionics, satellite electronics, or other high-value or mission-critical components. The plasma activation helps ensure strong adhesion and durability under extreme conditions. Parylene’s barrier properties (moisture, outgassing) are very useful for aerospace environments.

- Automotive & EV Coating of control units, battery electronics, sensors (e.g. ADAS, BMS) that need protection from chemical, thermal, and moisture stress. Very large chamber = high throughput for automotive-scale batches.

- Industrial / Harsh-Environment Sensors Sensors in chemical plants, oil & gas, renewable energy systems (wind / solar) where parts are exposed to humidity, corrosive gases, or dust. Control electronics for industrial automation that require long-life protection.

- Medical Devices Biocompatible coatings for implantable devices, catheters, micro-sensors. Parylene is used widely for medical applications. Volume production of medical components, where conformality, biocompatibility, and barrier performance are critical.

- Optoelectronics / PhotonicsTransparent, conformal protective coatings for LEDs, optical sensors, micro-optical devices. Large or many components per batch — leverages system’s chamber size.

- Micro / MEMS / Microstructures Scaling up from research to production: e.g. MEMS devices, microfluidics, or microstructures that need very uniform parylene coverage.The large chamber helps process many devices at once.

Book a Live or Virtual Demo

See the capabilities of our partners' equipment - including EVG, scia Systems, Veeco, PPS and SSI - in action. Experience tailored demonstrations designed around your process and application needs.