- Equipment Partners

- Products

- EV Group

- Bonding

- EVG®805

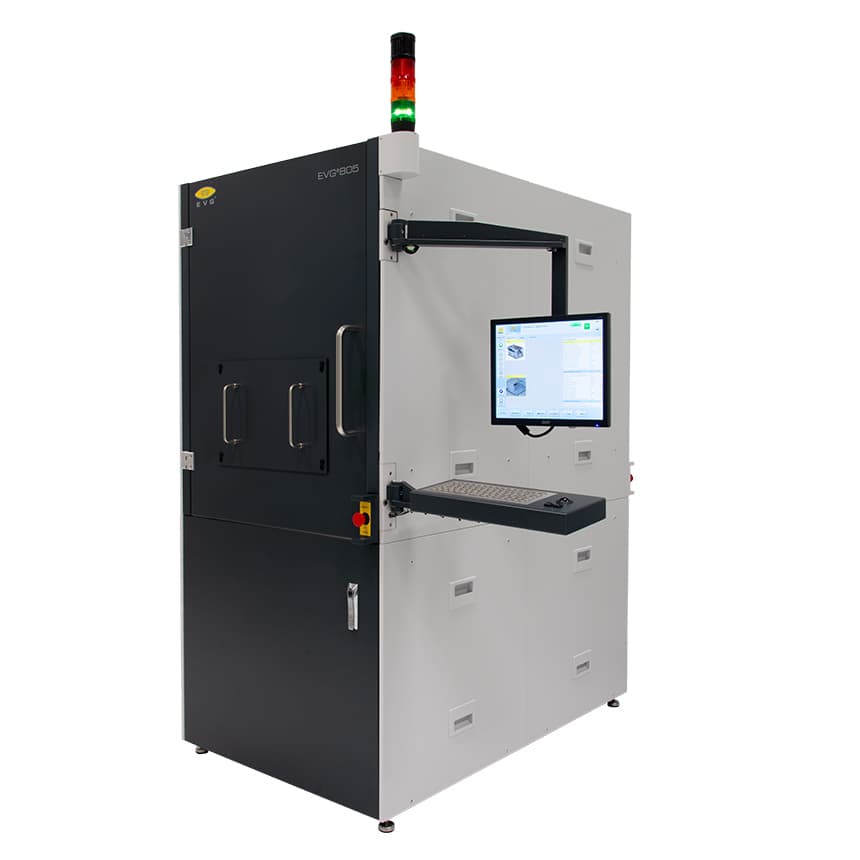

EVG®805

The EVG®805 is a specialised system for debonding temporarily bonded wafer stacks, which typically consist of a device wafer, a carrier wafer, and an intermediate temporary bonding adhesive.The system supports both thermal and mechanical debonding processes, providing flexibility based on specific needs. Once debonded, the thin wafer is safely unloaded onto a single substrate carrier, ensuring reliable transport between tools and minimising handling risks.

Features:

- Open adhesive platform

- Debond Options:

- Thermal slide off debonding

- Lift off debonding

- Mechanical debonding

- Recipe controlled system

- Real time monitoring and recording of all relevant process parameters

- Unique features for thin-wafer handling

- Various chuck designs to support wafer/substrates and carriers up to 300 mm

- High topography wafer handling

Applications:

- 3D Integration / Through‑Silicon Via (TSV) Processing

In 3D IC fabrication, thinning the device wafer and performing back-side processing often requires mechanical support by bonding to a carrier. After the steps, debonding is critical. The EVG 805 provides controlled debonding. - Power Devices / Compound Semiconductors

For power or wide bandgap devices, thinning to reduce resistance is common. Temporary bonding followed by debonding is often used. - Advanced Packaging / Fan-out / Wafer-level Processing

When dies/substrates need backside steps or handling after thinning, temporary bonding + debonding is part of the process chain. - MEMS Devices

MEMS often include thin or delicate membranes; temporary bonding helps during processing, and safe debonding is needed after. - Process Development / R&D

In research fabs and development labs exploring new bonding adhesives, debonding chemistries, and workflows, a flexible debonding tool like EVG 805 is important.

Book a Live or Virtual Demo

See the capabilities of our partners' equipment - including EVG, scia Systems, Veeco, PPS and SSI - in action. Experience tailored demonstrations designed around your process and application needs.