Equipment Modification and Refurbishment

Improve performance, extend equipment life and ensure compliance with an end-to-end modification and refurbishment service.

Whether you're upgrading high-value capital equipment for performance, ensuring CE or UKCA compliance, or retrofitting legacy equipment, our modification and refurbishment service is designed to help you keep your operations running efficiently and safely.

From initial audits and CAD schematics to hands-on retrofit installation and final testing, our expert team handles every stage in-house.

- 35+ years of experience

- End-to-end support

- UKCA, CE and PUWER compliance experts

Trusted By

What we do

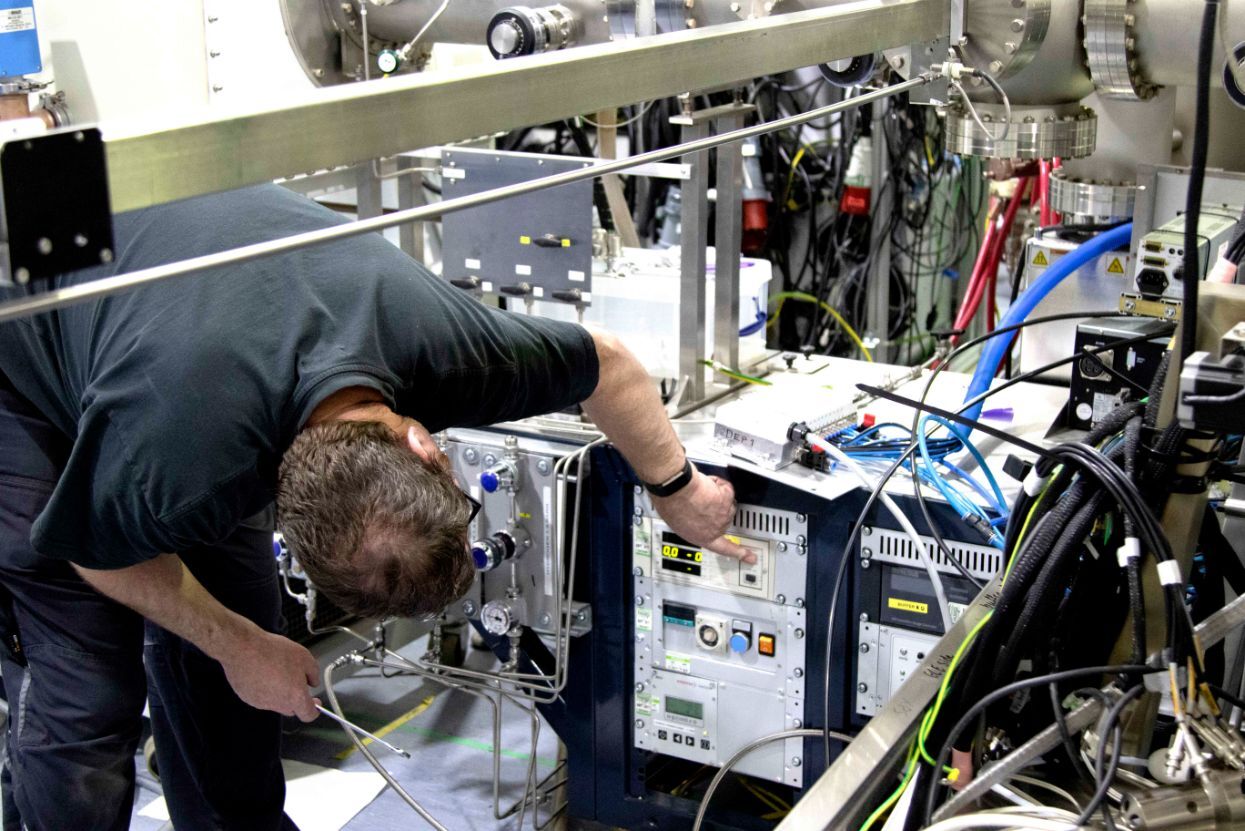

As part of our service, our qualified electrical and mechanical engineers can provide:

Full equipment audits and safety assessments

Manufacture of bespoke parts, panels and guards

Modification planning

Remedial work for HSE compliance

-

Including safety circuits and interlocks

Production of O&M manuals and preventive maintenance schedules for modified equipment

Compliance assessments and remedial work

Modifications testing

Customer demonstration prior to delivery or site integration

Reverse engineering to produce electrical and mechanical CAD schematics

Design and installation of electrical and mechanical upgrades

Why Work With Us?

-

35+ Years of capital equipment expertise

Work with a team that has 30+ years of experience modifying and refurbishing high-

value capital equipment -

Full compliance with expert testing

Ensure full CE, UKCA and PUWER compliance, with expert-led assessments, testing and documentation

-

Support from start to finish

Get full-service support, from concept and compliance through to installation and testing

-

Engineers who work with your team

Trust our engineers to work independently or alongside your in-house team

-

Custom manuals & maintenance plans

Get custom O&M manuals and maintenance schedules tailored to your modified equipment

Our Unique Capabilities

35+ Years of Expertise

Our team has decades of specialist expertise in upgrading and working with, high-value equipment.

End-to-end Support

From audit to installation, we handle the full equipment modification or refurbishment project in-house.

Compliance Expertise

Our experts ensure equipment meets essential safety and compliance standards through full risk assessments and remedial works.

Trusted by GE, Intel and Others

Our expert team of electrical and mechanical engineers have been working with high-value capital equipment for OEMs and end users across the globe since 1991.

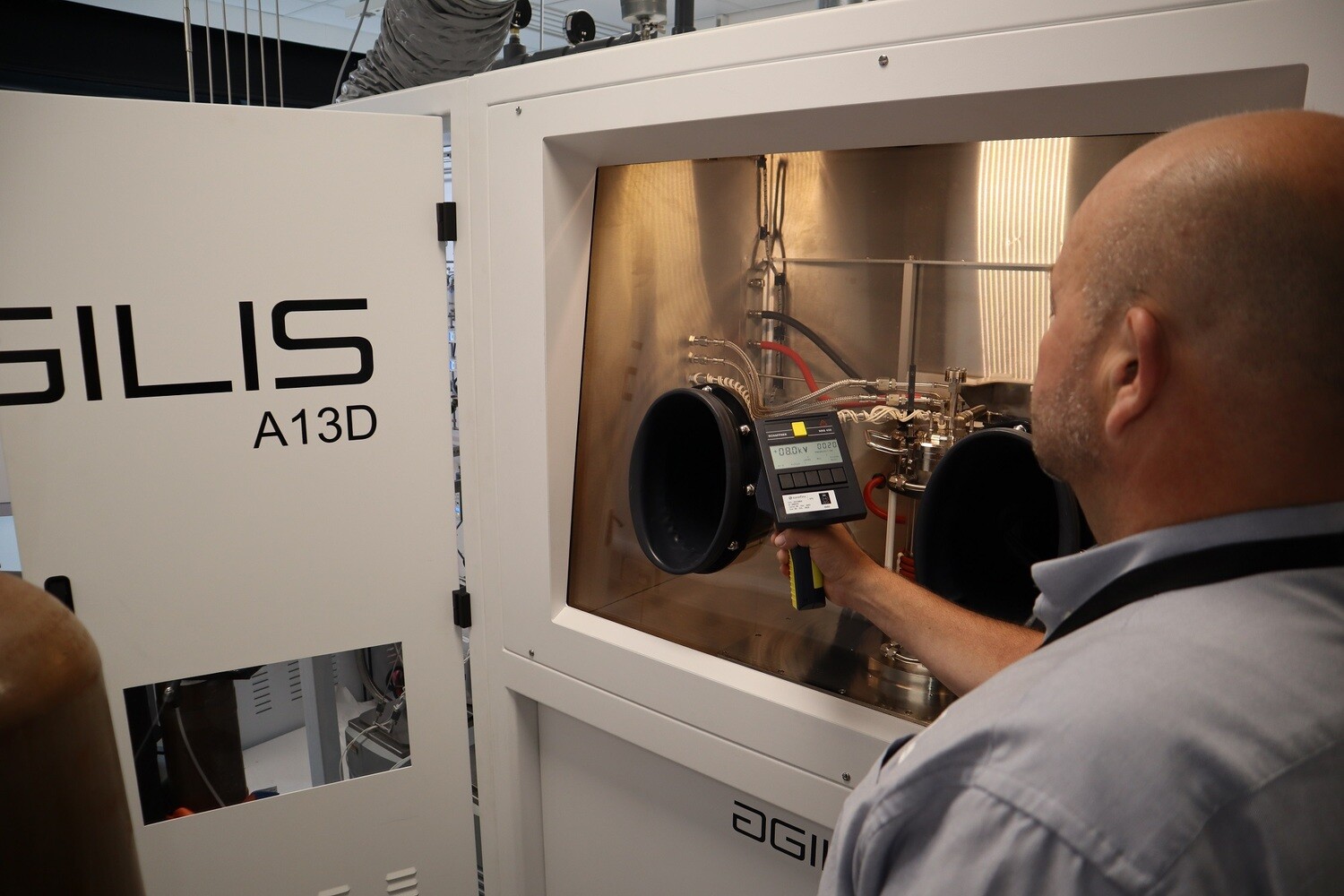

We have vast expertise in high-technology industries such as semiconductor, print, and pharmaceutical, working on a wide range of equipment, from ion implantation and lithography to digital print press equipment.

![]()

How we helped Plessey Semiconductors move and install more than 90 semiconductor tools into its cleanroom facility in 18 months.

How we helped VPS carry out LVD and EMC testing in just three days, enabling them to go to market more quickly and confidently.

How we helped Japanese Engineering Services (JES) complete a CE assessment at its factory in Turin, Italy, as safely as possible and with minimal downtime.

How we helped the University of Bristol relocate and successfully certify its Agnitron MOCVD reactor (the first of its kind in the UK) against UKCE regulations.

Additional Services

If you’re looking for more comprehensive support, we offer a whole host of services to help you with your project.

Ready to speak with one of our experts?

Request a callback from one of our team or a free quote for your job.