Pharmaceutical Equipment Moves

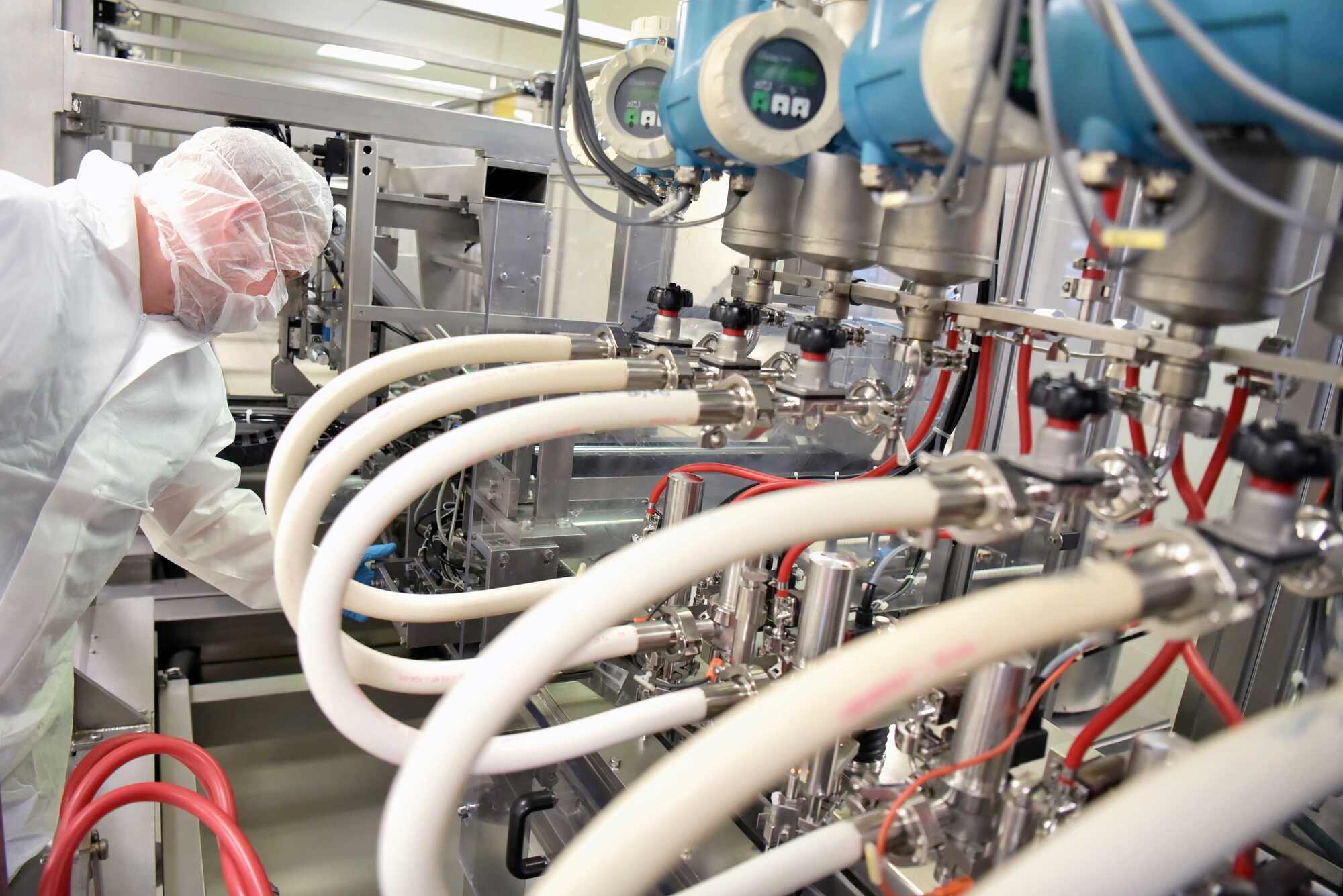

Move business-critical pharmaceutical equipment with total confidence

For more than 30 years, we’ve been working with complex biotechnology, life sciences, medical and pharmaceutical equipment in laboratories and cleanrooms worldwide.

Our all-in-one, start-to-finish service covers every step of your equipment relocation, from single production lines to full-site relocations.

Start-to-finish relocation partner for capital equipment

Cleanroom equipment specialist

Bespoke crate manufacturing and export packing service

Trusted By

Pharmaceutical Equipment Services

Whether you’re moving equipment for laboratories, cleanrooms or production facilities, our start-to-finish turnkey service covers every step of your high-technology equipment relocation:

|

|

Comprehensive site surveys, method statements and risk assessments |

|

|

Decontamination |

|

|

Dismantling and de-installation |

|

|

Equipment move-out |

|

|

Export packing |

|

|

Door-to-door freighting, including customs |

|

|

Equipment move-in |

|

|

Position, levelling, and alignment |

Additional Support Services

|

|

Structural machine bases |

|

|

Upgrades |

|

|

Compliance testing - including UKCA/CE marking and PUWER assessments |

Trusted by GE Healthcare, Abbott Labs, Catalent and more

We’ve been helping world-renowned pharmaceutical companies to move business-critical capital equipment since 1991.

How we helped Catalent move and install 18 tonnes of highly delicate critical equipment into its new laboratory.

How we helped Pirbright Institute to execute a first-of-its-kind laboratory equipment move alongside delicate livestock virus samples.

Pharmaceutical Equipment We Support

|

|

Capsule Filling Machines |

|

|

Tablet Coating Machines |

|

|

Blister Packers |

|

|

Cartoners |

|

|

Labelling Equipment |

|

|

Sealers |

|

|

Freeze Dryers and Tunnels |

|

|

Form Fillers |

|

|

Filling Lines |

Why Work With Us?

-

30 years’ experience

Over 30 years' of experience working with high-technology pharmaceutical equipment

-

Industry experts

Industry experts who understand equipment complexities and cleanroom protocols

-

Service you can rely on

A start-to-finish, end-to-end relocation service that you can rely on

-

Flexibility

Flexible teams that understand plans can change and will adapt to any new requirements

Speak with one of our experts

Request a callback from one of our team or book a site survey for your project.