- Equipment Partners

- Plasma Parylene Systems (PPS)

- Parylene Coating

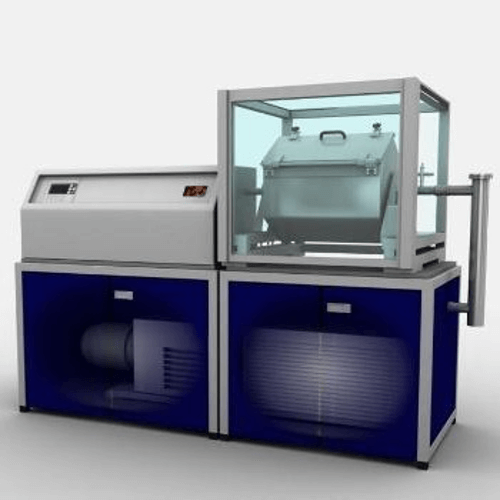

- Series 2000 with Rotary Drum

Series 2000 with Rotary Drum

This rotary drum system is designed for uniform parylene coating and even distribution across every substrate. With its integrated pump and cooling system, it delivers reliable performance in a compact footprint—ideal for smaller substrates and precision applications.

Key Features:

Enhanced Coating Uniformity

- The rotary drum design ensures even parylene distribution across complex or multiple surfaces—especially advantageous for small or intricately shaped parts.

Space-Efficient Design

- Balancing a compact footprint with robust functionality, the system is suitable for lab or production environments where space efficiency is important.

Scalability in Processing Capabilities

- Despite its modest size, the 80 L capacity and gas channel flexibility make it adaptable for evolving coating needs.

Reliable Operational Infrastructure

- The system’s built-in cooling, vacuum, and venting systems provide stable performance and simplified maintenance.

Technical Data:

- Dimensions: L: 2600mm W: 960 H: 1460mm

- Weight: ~ 200 KG

- Volume: 80 litres

- Process chamber: 400mm Ø H: 600mm

- Inclusive: 1 gas channel (gas distribution system inside the process chamber), up to 3 channels possible

- Cooling system: 4 liter (electromechanical Cool-trap)

- Vacuum connection: DIN 40 ISO-KF

- Venting: electromagnetic solenoid valve

- Pump system: 50m³/h

- Electrical connection: 3/N/PE AC 50Hz 400 V / 240 V, max. 8.5 KW

Speak with one of our experts

Request a callback from one of our team or book a site survey for your project.

.webp?width=250&height=145&name=ieslogo%20(5).webp)

-1.webp?width=588&height=164&name=ieslogo%20(5)-1.webp)