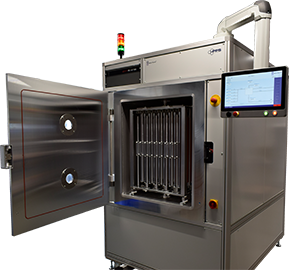

AL900

The AL 900 Control Active is an advanced, high-throughput desmearing plasma system engineered for efficient and uniform cleaning of large circuit board panels. Built for demanding industrial and R&D settings, it delivers powerful, customizable plasma desmearing through a robust, precision-controlled platform.

Key Features:

Large Processing Volume

- A capacious 900 L treatment chamber enables high-volume throughput for large-format substrates or multiple panels simultaneously.

Industrial-Scale Dimensions

- Footprint: 1,800 mm L × 1,500 mm W × 1,700 mm H

- Weight: 620 kg

Multi-Panel Capability

- Designed to process up to 18 circuit boards measuring 18 × 24″ or 20 × 24″ at once, significantly boosting productivity.

Dual Power Sources for Versatile Plasma Generation

- Low-Frequency (LF): 40 kHz, up to 10 kW—ideal for high-density ion generation.

- Microwave: 2.45 GHz, adjustable output from 50 to 1,200 W—for fine-tuned plasma control.

Integrated Gas Distribution System

- Comes standard with 3 gas channels, with options to expand up to 7 channels, enhancing flexibility for different process gases and recipes.

Modular Substrate Handling

- Optional custom-designed aluminum substrate holders allow greater flexibility and adaptability for diverse panel sizes or shapes.

Robust Vacuum & Venting Infrastructure

- Vacuum interface: DN 250 ISO-KF connection

- Venting: via electromagnetic solenoid valve—ensuring precise pressure control and rapid cycle times.

User-Friendly Design

- The hinged chamber door includes a viewing port for safe, convenient loading/unloading and visual process monitoring.

Technical Data:

- Dimensions: L: 1800mm W: 1500mm H: 1700mm

- Weight: 620 KG

- Volume: 900 Liter

- Porcess chamber: aluminum with electron cage:

- circuit boards: up to 18 panels mit 18x24" or 20x24"

- LF-output (Low Frequency): operating frequency = 40 KHz, up to 10 kW

- Microwave output: 2,45 GHz / 50 - 1200 Watt

- Inclusive: 3 gas channel (gas distribution system inside the process chamber), up to 7 channels available

- Substrate holder (optional): aluminium, custom design possible

- Vacuum connection: DN 250 ISO-KF

- Venting: electromagnetic solenoid valve

- Pump system: up to 600m³/h

- Chamber door: hinged-type with viewing port

Speak with one of our experts

Request a callback from one of our team or book a site survey for your project.

.webp?width=250&height=145&name=ieslogo%20(5).webp)

-1.webp?width=588&height=164&name=ieslogo%20(5)-1.webp)