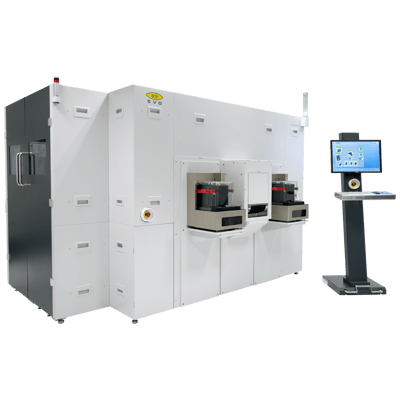

EVG®850 DB

This fully automated debonder provides the separation and cleaning of the processed temporary bonding wafer stack. The EVG850 DB ensures that the fragile device wafer is supported all the way through the tool, and supports debonding methods including UV laser, mechanical and thermal debonding. The device wafer is supported through a thin wafer handler or via film frame mounting.

Features

- Reliable handling of thinned, bowed and warped wafers with and without topography

- Automated cleaning of debonded wafer

- Recipe controlled system

- Real time monitoring and recording of all relevant process parameters

- Fully integrated SECS/GEM interface in automated tools

- Bridge tool capability for different substrate sizes

- Modular tool layout → throughput-optimized depending on specific process