Firebird

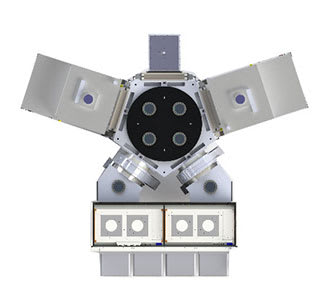

Veeco Firebird batch ALD system is an innovative, fully automated solution for high volume production of pinhole-free oxide layers for deposition of dielectrics, passivation, encapsulation, and seed layers films. Built on the proven Phoenix ALD system, the Firebird’s unique modular architecture decouples substrate heat-up and cool-down and mitigates wafer breakage with its innovative batch transfer design – a unique advantage for customers using fragile wafers such as LTO, LNO, and Glass.

Capable of handling 100, 150, 200, & 300mm wafers, the Firebird couples unmatched flexibility and performance at the lowest cost-of-ownership.

Features

- Batch deposition of oxide films for seed layers, encapsulation & barrier layers, optical coatings

- Effective parallel processing for best-in-class throughput

- Decoupled thermal management for preheat and cool-down

- Zero-wafer handling at elevated temperature for fragile / temperature sensitive substrates (glass, quartz, LNO/LTO, GaN)

- Flexible and upgradable modular configurability

- Seamless wafer scalability (100 to 300mm)

- SECS/GEM equipment communication

- SEMI S2 compliance

- Veeco worldwide sales, service and support

Configurability advantage

The modular system configuration can be effectively tailored to minimize process flow bottlenecks and offers outstanding processing flexibility.

2 reactors, 1 heat up module

1 reactor, 2 heat up modules

Flexibility and Ease-of-Use

The Firebird™ with its robust yet flexible reactor design delivers uncompromised process performance with seamless wafer size transition capability all the way up to 300mm.

Cost per Wafer Advantage

With its long campaigns and enhanced serviceability, Firebird™ meets and exceeds your cost-of-ownership requirements from small batch pre-production evaluation all the way to ramped-up production. Providing throughputs up to 40,000 wafers a month (based on 100 nm Al2O3 thickness), the Firebird™ combines best-in-class productivity, superior film performance and low cost of operation, leading to higher profitability for the most demanding customers.