Designing and Installing our Largest-Ever Structural Machine Base

The University of Southampton is a world leader in photonics and optoelectronics.

We're actively recruiting for a range of roles across sales, engineering, IT and warehouse. Check our careers page to see open positions including apprenticeships.

Whether you’re moving a single piece of equipment or an entire production line, our trusted team of engineers can support every step of your move, from rigging to end-to-end relocation support across the globe.

2 min read

Admin Feb 10, 2018 1:27:00 PM

SOLUT! is a sustainable packaging company based in Ohio, US, that produces high-strength, paper-based food trays for retailers, caterers and takeaways.

With demand for eco-friendly packaging on the rise, their team needed to expand production capacity quickly. But the usual route of ordering new equipment would have meant a two-year wait.

So, when three pre-owned thermoforming presses became available at WestRock’s UK site, SOLUT! wanted to move fast. But they needed a partner to get them safely across the Atlantic.

We were contracted to:

The equipment was heavy, the timeframe was tight, and the stakes were high.

Everything needed to arrive in perfect condition and be ready for immediate installation at their food technology facility.

Here’s how we did it.

Following a thorough site survey, we agreed our plan with our client and eagerly started work.

But when our team arrived on site to begin packing the equipment, we discovered that each unit was over four tonnes heavier than we expected.

That meant we had to completely reassess our original packing and lifting strategy on the spot so we could adhere to our plan.

We re-engineered our approach, adjusting the load calculations, securing upgraded lifting equipment, and modifying the crate designs and lashings to safely bear the true weight of the load.

Time was tight, but every detail had to be right.

A key challenge was that the presses had virtually no accessible points for securing them in transit.

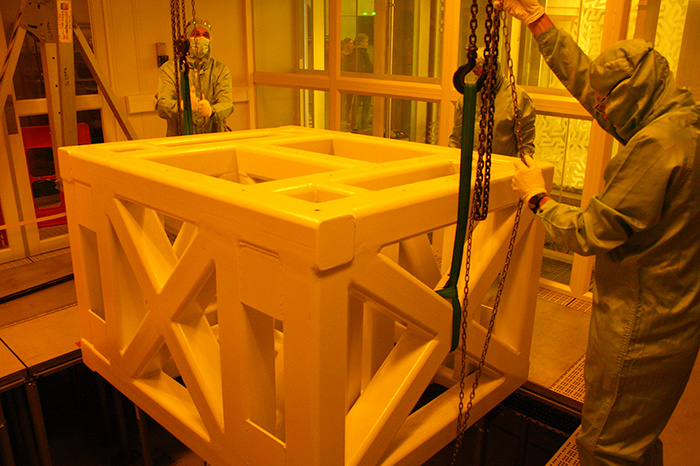

Using heat-treated ISPM15-compliant timber, we designed and fabricated bespoke wooden crates that offered full internal support.

This included:

The equipment was also vacuum-wrapped for moisture protection.

Every detail was designed to safeguard the integrity of the equipment and ensure it arrived installation-ready.

In total, the shipment consisted of 13 crates, packed with the three identical presses, each comprising of a main press, one unwind and one stacker, and additional accessories.

We oversaw every leg of the journey, from WestRock’s site in Bristol to the customer’s facility in Ohio.

That included:

Throughout the process, IES Business Development Manager Christian Malpas served as the single point of contact, keeping WestRock and SOLUT! fully informed every step of the way.

Christian also worked closely with SOLUT!’s receiving team in Ohio to confirm that they had the right kit ready for offload and positioning, avoiding any risk of installation delays.

Here’s what the President at SOLUT! had to say about working with us:

“IES were incredibly responsive, the crating was impressive and the team did a spectacular job. The team I worked with at our end have been in the business thirty years, and they felt the crating IES built was the most comprehensive they’ve ever seen. Just as we wanted, the machines arrived on time and in perfect condition, ready for us to install at SOLUT!"

Whether you’re moving high-value assets across the UK or around the world, our tailored crate manufacture and export packing services help you avoid risk and delays. No matter how large, heavy or complex the load.

Speak to our team about your next equipment move.

Stay up to date with the latest news and resources from our experts.

The University of Southampton is a world leader in photonics and optoelectronics.

HP is a global technology company that specialises in manufacturing personal systems, 3D printers and industrial digital presses for businesses...

Aged equipment gradually becomes more obsolete over time.